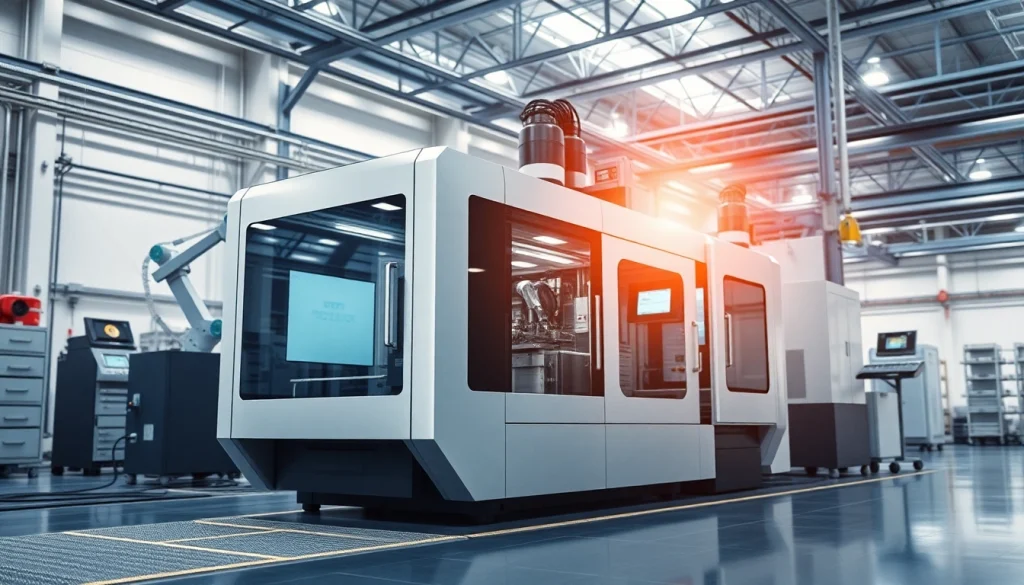

Understanding Electric Injection Molding Machines

In the evolving landscape of manufacturing, the electric injection molding machine stands out as a pivotal technology that enhances precision and efficiency. These machines are engineered to transform raw materials into high-quality plastic products with remarkable accuracy and speed. As the industry shifts toward sustainability, electric machines have gained traction due to their lower energy consumption, reduced emissions, and ability to produce complex parts at a lower cost per unit compared to traditional hydraulic machines.

What is an Electric Injection Molding Machine?

An electric injection molding machine is a type of machine that uses electric motors to drive the operational movements within the injection molding process. This differs from traditional hydraulic machines which rely on hydraulic fluid pressure. Electric machines are designed to deliver superior precision, repeatability, and energy efficiency, which are critical in modern manufacturing environments. The core functionality involves melting plastic pellets and injecting them into a mold to create a desired shape. The benefits of this technology include reduced cycle times, enhanced product quality, and lower operational costs.

Key Features and Advantages

- Precision Control: Electric machines utilize servo motors that provide real-time feedback and precise control over injection speed, pressure, and position.

- Energy Efficiency: By employing electric drive systems, these machines consume significantly less energy than their hydraulic counterparts, leading to reduced operational costs.

- Low Maintenance: Without hydraulic fluids, electric machines require less maintenance, which minimizes downtime and repair costs.

- Environmentally Friendly: The absence of hydraulic fluids and lower energy usage contribute to a smaller carbon footprint.

- Enhanced Product Quality: The stable process conditions ensure high dimensional accuracy and lower rates of defects in the produced parts.

Applications in Industry

Electric injection molding machines find applications across various industries, including automotive, medical, consumer goods, and electronics. They are particularly useful for creating complex components that demand high precision and repeatability. For instance, in the medical industry, they produce syringes, vials, and other intricate parts with stringent regulatory standards. Similarly, in the automotive sector, these machines manufacture precise components like dashboard parts and interior fixtures that require a high degree of consistency and reliability.

Topstar Electric Injection Molding Machine Series

Overview of TEII Series Features

The TEII series of all-electric injection molding machines from Topstar represents innovation in the molding process. With clamping forces ranging from 90T to 460T, these machines incorporate advanced features like high-rigidity templates for stable product manufacturing. The modular design allows for flexibility in various working conditions, while the optional linear rail provides lighter movement, enhancing operational efficiency.

Benefits of the TMII Series

The TMII series, a servo-driven injection molding machine, integrates multiple devices under a single control interface, making the molding process more streamlined. Features like automatic compensation at the mold opening position and real-time feedback enable precise grasping with injection molding robots. The TMII series is particularly effective for producing dense plastic products with complex geometries and tight tolerances.

Innovations in TH Series Machines

Designed for both small and large-scale production, the TH series machines provide a standardized clamping and injection platform tailored for deep-cavity, large-format products. The two-plate direct pressure structure maximizes mold opening stroke, making it ideal for automatic part-picking applications. This innovative design ensures that even the most challenging molds can be handled efficiently, boosting productivity in demanding environments.

Performance Metrics and Efficiency

Measuring Injection Precision

Precision in injection molding is a critical metric for manufacturers. Electric injection molding machines are known for their ability to deliver consistent and accurate injection across multiple cycles. The use of advanced servo motors allows for precise adjustments in the injection speed and pressure, contributing to minimal variance in product dimensions. This focus on precision is particularly vital in sectors where tolerance levels are extremely tight, such as aerospace and medical devices.

Energy Efficiency Standards

With rising energy costs and increasing environmental regulations, manufacturers are increasingly prioritizing energy efficiency. Electric injection molding machines typically operate with a power consumption of 30-70% less than hydraulic machines. This not only reduces energy expenses but also aligns with global sustainability trends, making electric machines an attractive option for manufacturers aiming to lower their carbon footprint.

Yield and Productivity Insights

Yield and productivity are crucial measures of the effectiveness of an injection molding machine. Electric machines typically provide faster cycle times due to their quick response to control signals. This leads to higher production rates and lower operating costs over time. Furthermore, the high precision of electric machines reduces scrap rates, thereby enhancing overall yield and profitability.

Challenges and Solutions in Electric Injection Molding

Common Misconceptions

One prevalent misconception about electric injection molding machines is their initial cost. While it is true that the upfront investment can be higher than hydraulic machines, the long-term savings in energy, maintenance, and operational efficiency often justify the cost. Additionally, users may overlook the versatility of electric machines when selecting a system for their operations.

Addressing Technical Challenges

Operational challenges, including the need for programming skill and the adaptation of existing molds, can arise when transitioning to electric machines. Manufacturers should invest in training and support to ensure smooth integration. Moreover, collaborating with machine suppliers can provide tailored solutions and assistance in adapting molds designed for hydraulic systems.

Future-Proofing Operations

To future-proof operations, manufacturers should prioritize selecting machines with modular designs that accommodate evolving technology and production requirements. Investing in machines that support Industry 4.0 technologies enables connectivity and data analysis, which can enhance operational oversight and predictive maintenance capabilities.

Trends and Future of Electric Injection Molding

Emerging Technologies and Innovations

The future of electric injection molding is heavily influenced by advancements in automation and artificial intelligence. Smart manufacturing technologies are being integrated into electric machines, allowing for greater oversight of production processes and maintenance scheduling. Furthermore, innovations such as IoT-enabled machines will enhance remote monitoring capabilities, providing real-time insights into machine performance.

Market Predictions for 2025

Industry experts predict significant growth in the electric injection molding market, driven by increased demand for high-precision components across various sectors. By 2025, the market is expected to expand as manufacturers pivot to energy-efficient solutions that align with sustainability goals and operational efficiency demands. This transition will likely accelerate the adoption of electric machines among new and existing manufacturing operations.

How to Stay Competitive in Manufacturing

To maintain competitiveness in the manufacturing landscape, companies must stay informed about advances in electric injection molding technologies. Regularly assessing production capabilities and investing in training for staff will ensure that operations can leverage new technologies effectively. Moreover, building collaborations with suppliers to explore innovative solutions will enhance production agility and responsiveness to market demands.